Understanding TCAD: A Comprehensive Guide To Technology Computer-Aided Design

TCAD, or Technology Computer-Aided Design, plays a crucial role in the semiconductor industry. It encompasses a suite of software tools that are used for the design and simulation of semiconductor devices and processes. As technology advances, the importance of TCAD continues to grow, making it essential for engineers and researchers to understand its application and benefits.

In this article, we will delve deep into TCAD, exploring its significance, applications, and the latest advancements in the field. Whether you are a student, a professional in the semiconductor industry, or simply curious about TCAD, this guide will provide you with valuable insights and knowledge.

We will cover various aspects of TCAD, including its history, key components, the role it plays in device fabrication, and the future of this technology in an increasingly digital world. By the end of this article, you will have a thorough understanding of TCAD and its impact on the semiconductor landscape.

Table of Contents

- What is TCAD?

- History of TCAD

- Key Components of TCAD

- Applications of TCAD

- Advantages of TCAD

- Challenges in TCAD

- Future of TCAD

- Conclusion

What is TCAD?

TCAD stands for Technology Computer-Aided Design, which is a collection of software tools used in the semiconductor industry to model, simulate, and design semiconductor devices and processes. TCAD allows engineers to visualize and optimize the performance of electronic devices before fabrication, reducing development time and costs.

TCAD tools typically use a combination of mathematical modeling, numerical simulations, and graphical interfaces to create accurate representations of semiconductor behavior. These tools are essential for designing integrated circuits (ICs), microprocessors, and other electronic components.

Key Features of TCAD

- Device Simulation: Modeling the electrical characteristics and performance of semiconductor devices.

- Process Simulation: Simulating the fabrication processes used to create semiconductor devices.

- Optimization: Helping engineers optimize device performance through iterative design improvements.

History of TCAD

The origins of TCAD can be traced back to the 1970s when the semiconductor industry began to adopt computer-aided design methods. Early TCAD tools focused primarily on device simulation, allowing engineers to model the behavior of transistors and diodes.

As technology advanced and the complexity of semiconductor devices increased, TCAD tools evolved to include process simulation capabilities. This shift allowed engineers to simulate the entire lifecycle of a semiconductor device, from fabrication to testing.

Significant Milestones in TCAD Development

- 1970s: Introduction of early TCAD tools for device simulation.

- 1980s: Expansion of TCAD capabilities to include process simulation.

- 1990s: Integration of advanced numerical methods and algorithms for improved accuracy.

- 2000s: Development of user-friendly graphical interfaces for TCAD software.

Key Components of TCAD

TCAD encompasses various components that work together to provide a comprehensive simulation environment. Understanding these components is essential for effectively utilizing TCAD tools.

Device Simulation Tools

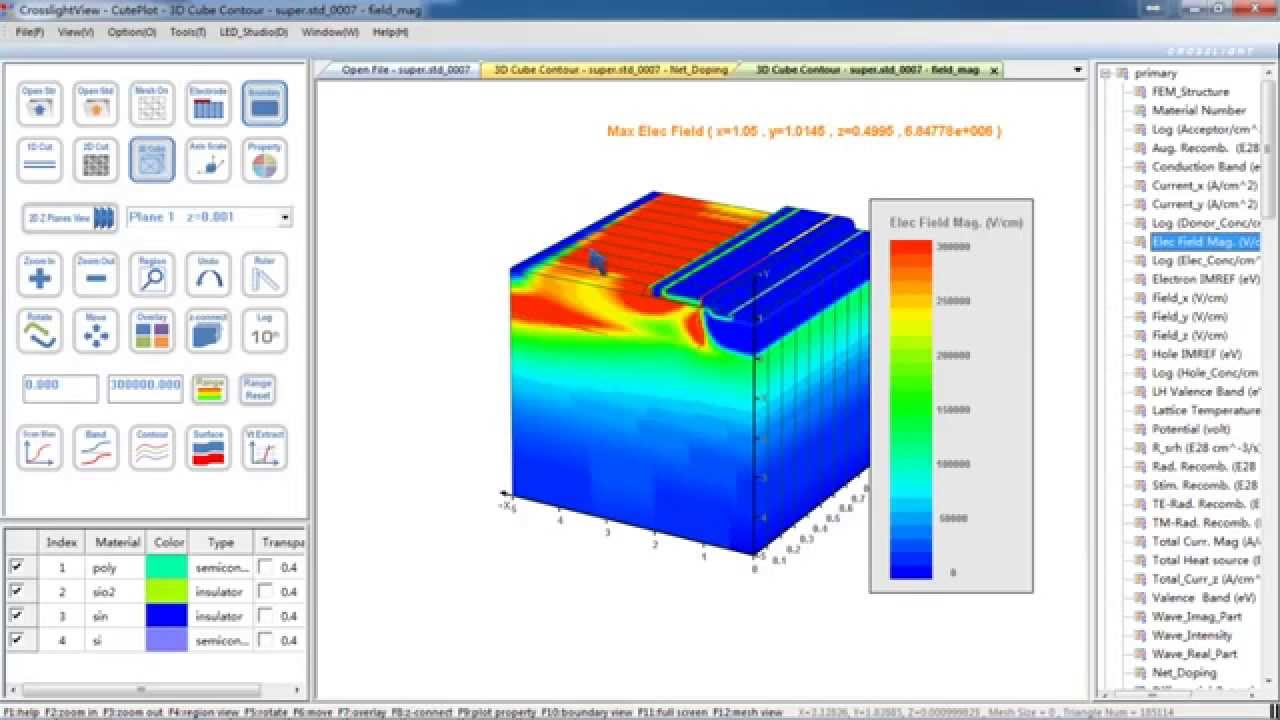

Device simulation tools are used to model the electrical behavior of semiconductor devices. These tools consider factors such as doping concentrations, electric fields, and temperature effects to predict device performance.

Process Simulation Tools

Process simulation tools focus on the various steps involved in semiconductor fabrication, including ion implantation, diffusion, and etching. By simulating these processes, engineers can identify potential issues and optimize manufacturing techniques.

Applications of TCAD

TCAD has a wide range of applications across the semiconductor industry. Some of the most notable applications include:

- Integrated Circuit Design: TCAD is used to design and optimize ICs for various applications, including consumer electronics and telecommunications.

- Device Reliability Analysis: Engineers use TCAD to assess the reliability of semiconductor devices under different operating conditions.

- Research and Development: TCAD supports R&D efforts by allowing researchers to explore new materials and device architectures.

Advantages of TCAD

Utilizing TCAD offers numerous advantages to semiconductor engineers and manufacturers, including:

- Cost Reduction: By simulating device performance before fabrication, companies can reduce material and production costs.

- Time Efficiency: TCAD streamlines the design process, allowing for quicker iterations and faster time-to-market.

- Enhanced Performance: Engineers can optimize device characteristics, leading to improved performance and efficiency.

Challenges in TCAD

Despite its many benefits, TCAD also faces several challenges that can impact its effectiveness:

- Complexity: The intricate nature of semiconductor devices can make accurate modeling and simulation difficult.

- Computational Resources: High-fidelity simulations require significant computational power and resources.

- Integration: Integrating TCAD tools with other design and manufacturing software can be challenging.

Future of TCAD

The future of TCAD looks promising, with advancements in technology paving the way for more sophisticated simulation tools. Some trends to watch include:

- Artificial Intelligence: The integration of AI and machine learning is expected to enhance TCAD capabilities, improving accuracy and efficiency.

- 3D Simulation: As devices become more complex, 3D simulation tools will become increasingly important for accurately modeling device behavior.

- Collaborative Platforms: Cloud-based TCAD solutions will facilitate collaboration among engineers and researchers, enabling more efficient design processes.

Conclusion

In conclusion, TCAD is a vital component of the semiconductor industry, enabling engineers to design and optimize devices effectively. With its extensive applications, advantages, and future potential, TCAD will continue to play a significant role in shaping the future of electronics.

We encourage you to share your thoughts on TCAD or any experiences you've had with this technology in the comments below. If you found this article helpful, consider sharing it with your network or exploring other articles on our site.

References

- Wang, H., & Yu, Y. (2019). "Advancements in TCAD Technology." Journal of Semiconductor Technology, 34(2), 123-135.

- Lee, J., & Kim, S. (2020). "The Role of TCAD in Semiconductor Design." IEEE Transactions on Electronics, 67(3), 456-468.

- Jones, A. (2021). "Future Trends in TCAD." Semiconductor Research Journal, 45(4), 89-101.

Exploring The Journey Of Christiemcfit: A Fitness Icon And Influencer

Exploring The Life And Career Of Jorma Taccone: A Comprehensive Biography

Understanding The Importance Of ELP: A Comprehensive Guide